Conducting a strategic review of winery processes and procedures can lead to significant gains in efficiencies and reduce labour costs.

All wineries need to clean. Cleaning (and sanitising) ensures that winemakers can control what goes into wine and what doesn’t. This inevitably means that wineries will have to spend money on hygiene products. Most will do what they did last year, or the year before. While this may seem like an attractive proposition, it does pay off in the long-term to think strategically about your hygiene needs, and make purchasing decisions with those strategic requirements in mind.

To be strategic we need to take a holistic view of the cost inputs with our cleaning and hygiene procedures. Many cost comparisons of hygiene products only consider the chemical cost, and don’t take into account all the real costs and opportunity costs associated with cleaning. Chemical cost is a part of the real cost of winery hygiene, but so is labour cost, efficacy costs (having to conduct repeat processes) and additional process requirements (think citric rinses after caustic washes). The opportunity costs, while hard to evaluate and predict, can be devastating if not accounted for appropriately. They include environmental impact, safety and spoilage risks. The view that chemical cost is the only important factor in winery hygiene costings is very simplistic, and it could be doing damage to your bottom line.

Real Costs

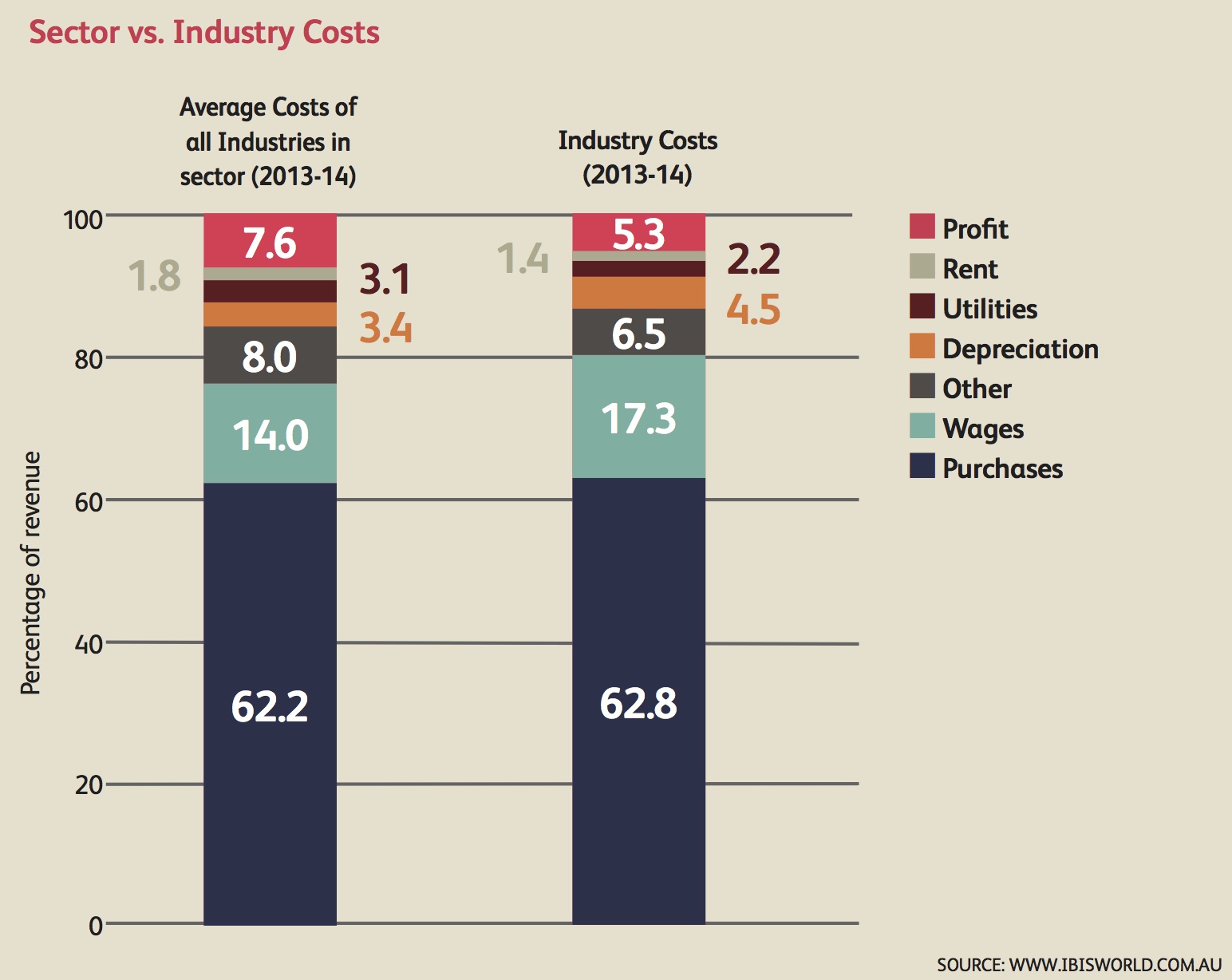

Let’s start with labour, which according to the November 2013 IBISWorld wine report, accounts for 17.3% of revenue in wine production (Lin 2013, p.24). At almost a fifth of the industry average total revenue generated, this equates to a significant amount of money spent on labour in wine production. Furthermore for every $1.00 that is paid as a labour expense a further $0.26 is required to be spent on capital investments (Lin 2013, p.35). What we see here is that the wine industry on average, spends 3.3% more of total revenue on labour costs compared to all other industries (Lin 2013, p.24). The take home message is that reducing labour costs can increase your annual revenue intake and the modern winery should be seeking out efficiency improvements to reduce their labour overheads.

Figure 1: Wine sector costs vs Industry Costs (Lin 2013, p.24)

Another significant winery hygiene cost is chemical. This cost is harder to quantify as tank sizes vary, tartrate levels change and there is volatility in the price of chemicals, quality and the quantity. Water is another cost in winery hygiene, and while in comparison to labour and chemical costs, it is much smaller, any reduction in water usage is a cost saving and is environmentally more efficient.

Let’s take a look at one of the more popular cleaning agents used in wineries, sodium hydroxide (or caustic soda) and what it actually costs to clean a tank. Most wineries will undertake the following process to clean a tank when cleaning with sodium hydroxide:

- Single pass water rinse

- Sodium hydroxide circulation

- Single pass water rinse

- Citric acid circulation

- Single pass water rinse

The standard procedure for cleaning with sodium hydroxide is use a 1-2% w/v aqueous solution first, and then perform a citric acid rinse of 0.5-1% w/v (to reduce the pH level of any residual chemical). Sodium hydroxide comes in two forms - as a liquid or in a solid pearl form. When reviewing pricing the cheapest commodity price we could find for bulk purchases was $0.65 per litre for the liquid and in a pearl it was $1.00 per kg. Citric acid costs between $1.25-$1.50 per kg.

Chemical Input Costs

Table 1: Sodium Hydroxide and Citric Acid chemical costs per wash.

The total chemical input cost for the liquid price is almost $6 per tank and the average price is $8.50 for a 20kL tank. If it were only this cheap to clean a tank! The issue is that staff are required to set the pumps and equipment up in order to achieve this and this is where the exercise becomes expensive.

Labour Costs

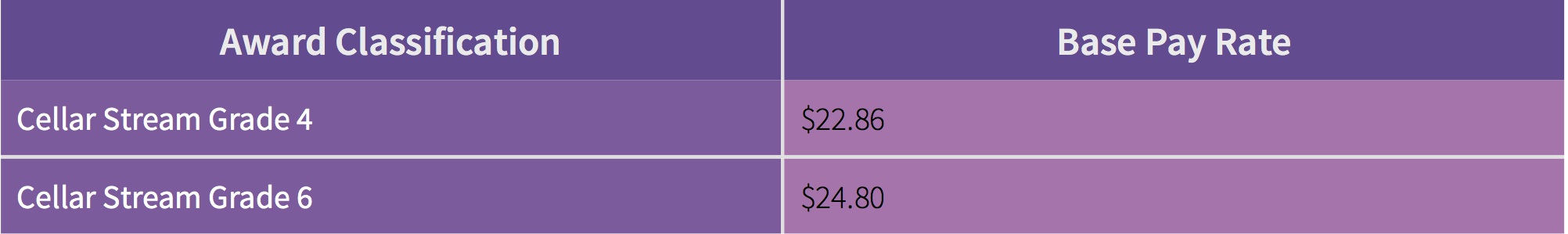

Table 2: Wine Industry Award Wages (FairWork Ombudsmen 2012, pp.4-9)

If we presume it takes 30-60 minutes to clean a tank, we can see that the labour cost far outweighs the chemical cost. If we take the Cellar Stream Grade 4 award then it costs $0.38 for every extra minute that is spent cleaning tanks in labour. Looking at this strategically, it makes sense to be looking at ways to minimise time that staff are spending cleaning. The more efficient they are the more of the 17% of total revenue that you’ll have back in your pockets!

Our focus at AIRD has always been on reducing processes, that is, cleaning smarter. One of the first processes that can be eliminated by using AIRD products is a citric rinse. If it takes 5-10 minutes to run a citric rinse on each tank, it is actually costing between $1.90 and $3.80 per tank in additional labour expenditure. Over the course of a vintage this adds up significantly (just think how many times your tanks are cleaned in a vintage). None of our products require a citric rinse, which reduces your cost input for each wash.

Eliminating a citric rinse also eliminates the need for a water rinse after the citric also - and if it takes 2-5 mins for a single pass water rinse then there is a cost of $1.14 - $1.90 which can be saved. If you were looking to compare the process for Aird cleaning chemicals including Cleanskin® the process is as follows:

- Single pass water rinse

- Cleanskin circulation

- Single pass water rinse

So a five step process has been reduced to a three step process - with better chemical inputs. Labour processes have been reduced significantly with Cleanskin® saving between $3.04 - $5.70 per tank in labour costs. Streamlining processes is not only working efficiently but it reduces labour costs significantly.

More efficient processes and better inputs reduce the likelihood of tanks requiring a repeat clean. There is a high cost for every time a tank needs a second clean with sodium hydroxide because five steps are necessary to work through in order to clean. Sodium hydroxide as a commodity will also leave a protein stain in tanks. An overwhelming majority of wineries we have spoken to in relation to protein staining will either treat protein stains with additional chemical or get staff to get in and scrub tanks where they can reach. For each tank labour costs to re-clean tanks are $0.38 per minute plus additional chemical required.

There are savings to be made in reducing processes and making cleaning a more efficient process. Investing in better inputs means that less time is spent repeat cleaning and without the need for old fashioned citric rinses.

Product Comparison

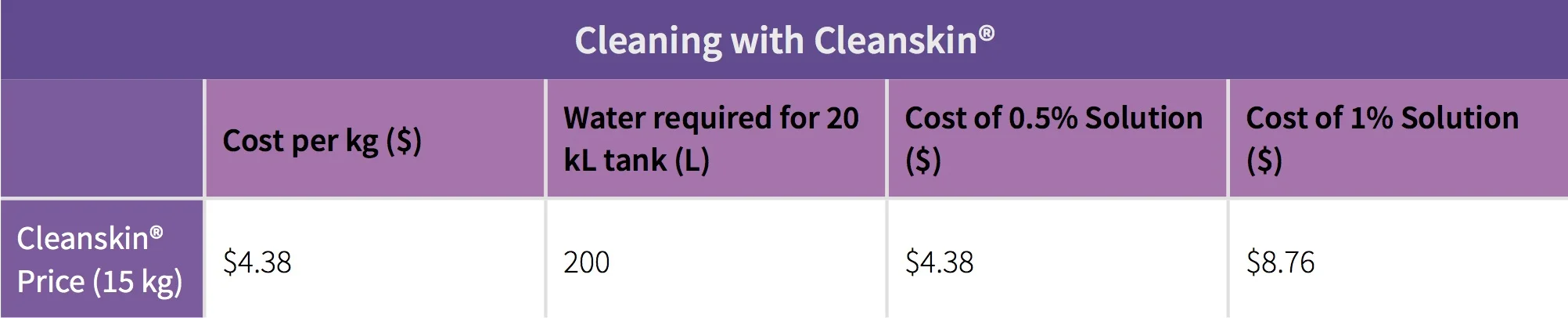

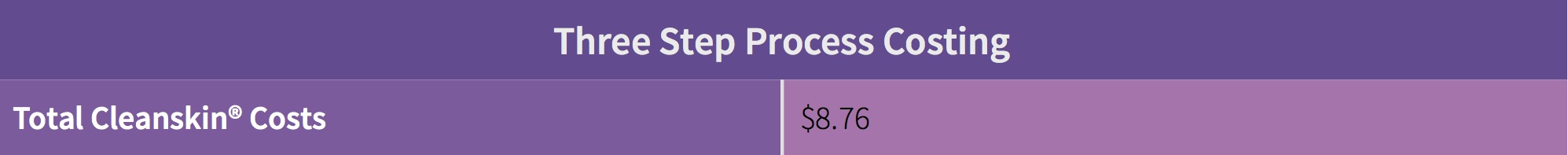

Still not convinced? Lets look at what it would cost to clean a tank with Cleanskin®:

Table 3: Cleanskin® chemical cost per wash

When you include the labour time to undertake a citric and water rinse it becomes extremely close regarding input costs. The additional processes of a 5-10 minute citric rinse and a 3-5 minute water rinse required for cleaning with sodium hydroxide are costing you an additional $0.18 per tank when compared to Cleanskin®. If you are paying more than $0.65 per L for your sodium hydroxide it becomes much more expensive.

Table 4: Caustic/Citric overall cost per wash

Table 5: Cleanskin® overall cost per wash

So not only is Cleanskin® cheaper, but the other benefit is that the chemical you’re using will not leave protein stains in your tanks - leaving you with less repeat cleaning to undertake. It makes staff more efficient, your hygiene much better and your approach to cleaning more strategic.

Opportunity Costs

This brings us to opportunity costs, which is essentially a cost for not doing something (oftentimes described as the cost of missing out on the benefit of not doing something). This cost does vary, and the nature of opportunity costs are somewhat speculative, however they are real, and can result in serious long-term consequences if not taken into account. It is well known that biofilming from protein stains enables yeasts, bacteria and microbes to persist in tanks. This can lead to issues such as taint, or unwanted microbe contamination of your finished product. The opportunity costs here are the loss of income due to poor wine quality, and then the necessary costs to manage or remove the unwanted microbes from your winery. In comparison, the real costs of cleaning properly are much cheaper than the opportunity costs in this scenario. Better hygiene is better protection for your wine.

That was just one example of opportunity costs in your winery. There are plenty more such as; work, health and safety and environmental management to name a few. It is important that in your strategic thinking about cleaning, you look at the opportunity costs and how they may impact upon your winery, and then make a decision weighing up all the benefits.

Conclusion

In the end, the strategic move is to know what your costs are and how they relate to the finished product. You may be surprised to learn that a premium product not only is cheaper in the long-term (through reduced labour costs), but better for your wine and therefore better for your bottom line!

References

Lin, R 2013 ‘IBISWorld Industry Report C1214: Wine Production in Australia’, IBISWorld, Nov. 2013,www.ibisworld.com.au/gosample.aspx?cid=61&rtid=101?, accessed 2013-12-03

FairWork Ombudsmen 2012 ‘Wine Industry Award: Pay and Conditions Guide’, Australian Government,http://wgcsa.com.au/wp-content/uploads/Wine-Industry-Award-Rates-and-Conditions-01-06-2012.pdf, accessed 2013-12-03