The real cost of cleaning

Conducting a strategic review of winery processes and procedures can lead to significant gains in efficiencies and reduce labour costs.

Conducting a strategic review of winery processes and procedures can lead to significant gains in efficiencies and reduce labour costs.

All wineries need to clean. Cleaning (and sanitising) ensures that winemakers can control what goes into wine and what doesn’t. This inevitably means that wineries will have to spend money on hygiene products. Most will do what they did last year, or the year before. While this may seem like an attractive proposition, it does pay off in the long-term to think strategically about your hygiene needs, and make purchasing decisions with those strategic requirements in mind.

To be strategic we need to take a holistic view of the cost inputs with our cleaning and hygiene procedures. Many cost comparisons of hygiene products only consider the chemical cost, and don’t take into account all the real costs and opportunity costs associated with cleaning. Chemical cost is a part of the real cost of winery hygiene, but so is labour cost, efficacy costs (having to conduct repeat processes) and additional process requirements (think citric rinses after caustic washes). The opportunity costs, while hard to evaluate and predict, can be devastating if not accounted for appropriately. They include environmental impact, safety and spoilage risks. The view that chemical cost is the only important factor in winery hygiene costings is very simplistic, and it could be doing damage to your bottom line.

Real Costs

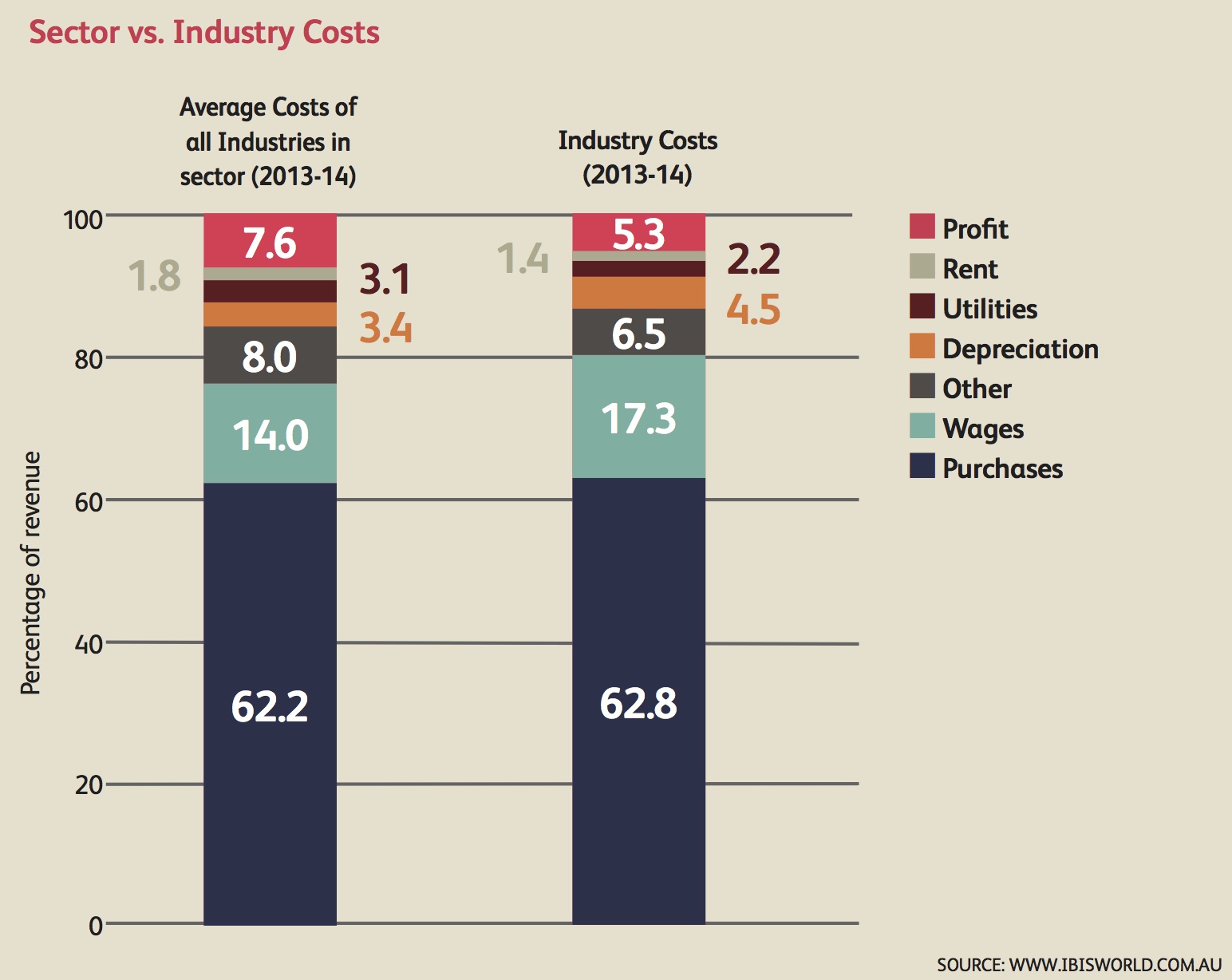

Let’s start with labour, which according to the November 2013 IBISWorld wine report, accounts for 17.3% of revenue in wine production (Lin 2013, p.24). At almost a fifth of the industry average total revenue generated, this equates to a significant amount of money spent on labour in wine production. Furthermore for every $1.00 that is paid as a labour expense a further $0.26 is required to be spent on capital investments (Lin 2013, p.35). What we see here is that the wine industry on average, spends 3.3% more of total revenue on labour costs compared to all other industries (Lin 2013, p.24). The take home message is that reducing labour costs can increase your annual revenue intake and the modern winery should be seeking out efficiency improvements to reduce their labour overheads.

Figure 1: Wine sector costs vs Industry Costs (Lin 2013, p.24)

Another significant winery hygiene cost is chemical. This cost is harder to quantify as tank sizes vary, tartrate levels change and there is volatility in the price of chemicals, quality and the quantity. Water is another cost in winery hygiene, and while in comparison to labour and chemical costs, it is much smaller, any reduction in water usage is a cost saving and is environmentally more efficient.

Let’s take a look at one of the more popular cleaning agents used in wineries, sodium hydroxide (or caustic soda) and what it actually costs to clean a tank. Most wineries will undertake the following process to clean a tank when cleaning with sodium hydroxide:

- Single pass water rinse

- Sodium hydroxide circulation

- Single pass water rinse

- Citric acid circulation

- Single pass water rinse

The standard procedure for cleaning with sodium hydroxide is use a 1-2% w/v aqueous solution first, and then perform a citric acid rinse of 0.5-1% w/v (to reduce the pH level of any residual chemical). Sodium hydroxide comes in two forms - as a liquid or in a solid pearl form. When reviewing pricing the cheapest commodity price we could find for bulk purchases was $0.65 per litre for the liquid and in a pearl it was $1.00 per kg. Citric acid costs between $1.25-$1.50 per kg.

Chemical Input Costs

Table 1: Sodium Hydroxide and Citric Acid chemical costs per wash.

The total chemical input cost for the liquid price is almost $6 per tank and the average price is $8.50 for a 20kL tank. If it were only this cheap to clean a tank! The issue is that staff are required to set the pumps and equipment up in order to achieve this and this is where the exercise becomes expensive.

Labour Costs

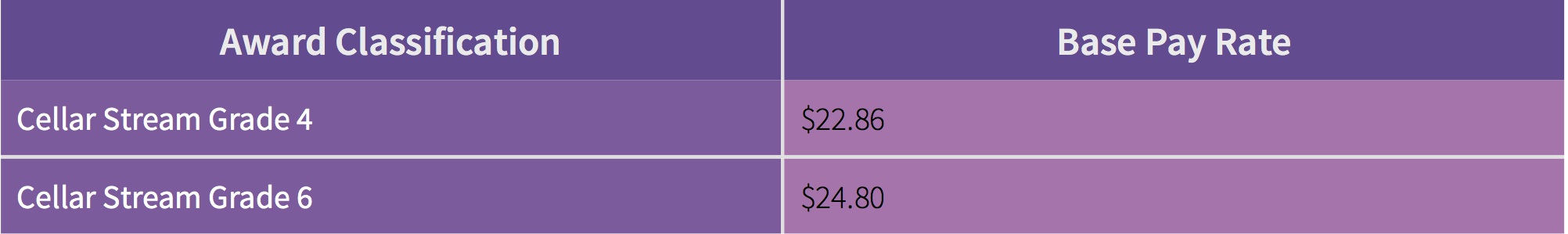

Table 2: Wine Industry Award Wages (FairWork Ombudsmen 2012, pp.4-9)

If we presume it takes 30-60 minutes to clean a tank, we can see that the labour cost far outweighs the chemical cost. If we take the Cellar Stream Grade 4 award then it costs $0.38 for every extra minute that is spent cleaning tanks in labour. Looking at this strategically, it makes sense to be looking at ways to minimise time that staff are spending cleaning. The more efficient they are the more of the 17% of total revenue that you’ll have back in your pockets!

Our focus at AIRD has always been on reducing processes, that is, cleaning smarter. One of the first processes that can be eliminated by using AIRD products is a citric rinse. If it takes 5-10 minutes to run a citric rinse on each tank, it is actually costing between $1.90 and $3.80 per tank in additional labour expenditure. Over the course of a vintage this adds up significantly (just think how many times your tanks are cleaned in a vintage). None of our products require a citric rinse, which reduces your cost input for each wash.

Eliminating a citric rinse also eliminates the need for a water rinse after the citric also - and if it takes 2-5 mins for a single pass water rinse then there is a cost of $1.14 - $1.90 which can be saved. If you were looking to compare the process for Aird cleaning chemicals including Cleanskin® the process is as follows:

- Single pass water rinse

- Cleanskin circulation

- Single pass water rinse

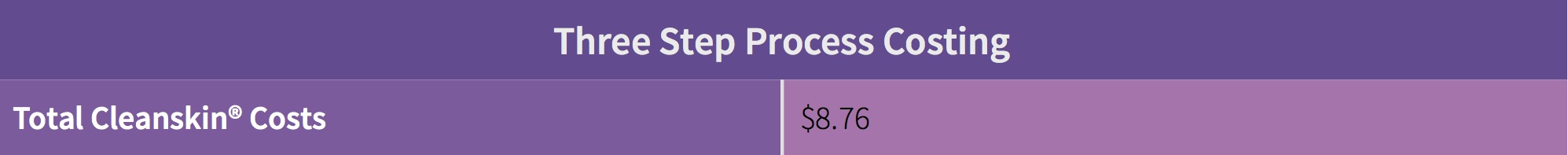

So a five step process has been reduced to a three step process - with better chemical inputs. Labour processes have been reduced significantly with Cleanskin® saving between $3.04 - $5.70 per tank in labour costs. Streamlining processes is not only working efficiently but it reduces labour costs significantly.

More efficient processes and better inputs reduce the likelihood of tanks requiring a repeat clean. There is a high cost for every time a tank needs a second clean with sodium hydroxide because five steps are necessary to work through in order to clean. Sodium hydroxide as a commodity will also leave a protein stain in tanks. An overwhelming majority of wineries we have spoken to in relation to protein staining will either treat protein stains with additional chemical or get staff to get in and scrub tanks where they can reach. For each tank labour costs to re-clean tanks are $0.38 per minute plus additional chemical required.

There are savings to be made in reducing processes and making cleaning a more efficient process. Investing in better inputs means that less time is spent repeat cleaning and without the need for old fashioned citric rinses.

Product Comparison

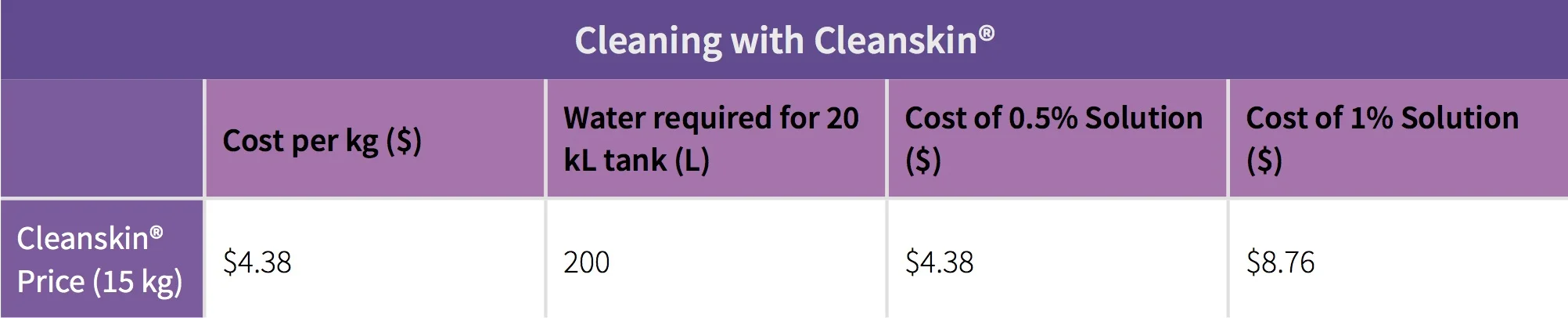

Still not convinced? Lets look at what it would cost to clean a tank with Cleanskin®:

Table 3: Cleanskin® chemical cost per wash

When you include the labour time to undertake a citric and water rinse it becomes extremely close regarding input costs. The additional processes of a 5-10 minute citric rinse and a 3-5 minute water rinse required for cleaning with sodium hydroxide are costing you an additional $0.18 per tank when compared to Cleanskin®. If you are paying more than $0.65 per L for your sodium hydroxide it becomes much more expensive.

Table 4: Caustic/Citric overall cost per wash

Table 5: Cleanskin® overall cost per wash

So not only is Cleanskin® cheaper, but the other benefit is that the chemical you’re using will not leave protein stains in your tanks - leaving you with less repeat cleaning to undertake. It makes staff more efficient, your hygiene much better and your approach to cleaning more strategic.

Opportunity Costs

This brings us to opportunity costs, which is essentially a cost for not doing something (oftentimes described as the cost of missing out on the benefit of not doing something). This cost does vary, and the nature of opportunity costs are somewhat speculative, however they are real, and can result in serious long-term consequences if not taken into account. It is well known that biofilming from protein stains enables yeasts, bacteria and microbes to persist in tanks. This can lead to issues such as taint, or unwanted microbe contamination of your finished product. The opportunity costs here are the loss of income due to poor wine quality, and then the necessary costs to manage or remove the unwanted microbes from your winery. In comparison, the real costs of cleaning properly are much cheaper than the opportunity costs in this scenario. Better hygiene is better protection for your wine.

That was just one example of opportunity costs in your winery. There are plenty more such as; work, health and safety and environmental management to name a few. It is important that in your strategic thinking about cleaning, you look at the opportunity costs and how they may impact upon your winery, and then make a decision weighing up all the benefits.

Conclusion

In the end, the strategic move is to know what your costs are and how they relate to the finished product. You may be surprised to learn that a premium product not only is cheaper in the long-term (through reduced labour costs), but better for your wine and therefore better for your bottom line!

References

Lin, R 2013 ‘IBISWorld Industry Report C1214: Wine Production in Australia’, IBISWorld, Nov. 2013,www.ibisworld.com.au/gosample.aspx?cid=61&rtid=101?, accessed 2013-12-03

FairWork Ombudsmen 2012 ‘Wine Industry Award: Pay and Conditions Guide’, Australian Government,http://wgcsa.com.au/wp-content/uploads/Wine-Industry-Award-Rates-and-Conditions-01-06-2012.pdf, accessed 2013-12-03

It’s time we stopped using commodity caustic in Australia

Commodity caustic soda (Sodium Hydroxide) is used regularly in wineries globally, however we at AIRD believe that commodity caustic is wasting money, ineffective and dangerous for use in your winery. Find out why.

Yes it’s cheap and it’s ubiquitous, but it may be doing damage to your wine and equipment, but let’s first look at the pros. Caustic is very good at quickly removing heavy deposits of wine solids with tartar whilst its pH is in the range 10-14 and used with potable water in ambient temperature range of 20-40°C. These few benefits are the main reasons why it has become so widely used throughout the global wine industry.

As caustic is a sodium product, it is potentially environmentally degrading (high sodium effluent can cause sodic soils), corrosive to most contact surfaces, creates high HR risk in use (burns to skin and eyes) and is not as an effective cleaning agent as you might think. In addition to that, think of all of the extra paperwork and cartage cost required in transporting, on-site handling and storage; on site HR supervision; as well as the safety equipment required and maintenance for its use.

The pH differential between caustic and wine is 14 to 3.5 respectively, and the salt, whilst effective in decolourising and dissolving the organic soil, denatures and chars it at the same time (evidenced by red wine colour converting to a charcoal). At the same time, as a common salt derivative it increases surface tension which reduces likelihood of the removal of the protein. When cleaning with caustic, often biofilm/protein char presents on surfaces after the process which requires large amounts of hot water and a mechanical action (high pressure pump spray) with task specific cleaning agents or often scrubbing in smaller tanks with only water (or a safe-to-use chemical) to simply to remove this film.

With all of this there is still no guarantee that you have eliminated layered protein char-stain from your stainless equipment, most particularly in large stainless steel tanks. It has become common practice to rinse with a low dose aqueous citric acid after the caustic cleaning process to neutralize any residual sodium salt and reduce Ca/Mg scale. This process will not remove the charred biofilm, (as you may well have already experience), and this biofilm is the perfect breeding ground for Brettanomyces to flourish within your tanks.

In an attempt to fix this ‘filming’ problem where there are heavy stains, rather than re-cleaning equipment with more reliable cleaning products, it has become common practice in some wineries to increase the concentration of the caustic solution and increase ‘cleaning in place’ (CIP) circulation time. What you need to understand and what we are trying to stress is, simply putting more caustic in and leaving it there for longer won’t remove the bio-film but may in-fact, exacerbate it. If you increase the concentration of caustic in solution, you run the risk of premature ageing of your assets (e.g. pitting in the stainless surfaces of your tanks), and you increase the danger for your employees having to mix a dangerous good in higher proportions, which can cause severe burns if it comes in contact with skin or eyes. Caustic is strongly reactive with aluminium and can cause degradation of glass surfaces, so not only do you have to be careful about where and how you store it, but also how you use it.

So let’s look at some more chemistry. When a quantity of caustic soda granules (pearl) comes into contact with a small volume of water it creates a strong exothermic reaction which can be dangerous to users as it can cause high pH vapour, which then comes into contact with the skin, or worse, the eyes. If you are using hot water in your cleaning process (which we would strongly recommend), a much more volatile and dangerous ‘spitting’ reaction occurs upon contact of caustic with water. The highly alkali pH of caustic solution can lead to blindness if it comes into contact with your eyes. So the real question is, why risk this happening to your trained cellar staff, or even to yourself if you are the all-in-one person in a small/micro winery?

Yes, caustic is cheap. However, when a staff member is injured due to using a dangerous good, workplace injury claims aren’t cheap; and wasting wine isn’t cheap when your wine tanks and lines aren’t really satisfactorily and they become infected with unwanted microbes. It’s simply not worth it. It’s time to use your grey matter, look across the spectrum and compare the greater negatives with the few positives for commodity caustic soda. The alternatives now available are far more effective at cleaning your surfaces, safer for you and your wine and require less effort to get the job done correctly the first time - but that’s a conversation for another time.

If you have any questions about caustic alternatives, then get in touch, because it is time to stop using caustic, it’s time to start cleaning smarter, safer and cleaner.

Caustic ineffective against mature Biofilms

A recent article in Food Quality News demonstrated that mature salmonella biofilms were not able to be removed by sodium hypochlorite, sodium hydroxide and benzalkonium.

A recent article in Food Quality News demonstrated that mature salmonella biofilms were not able to be removed by sodium hypochlorite, sodium hydroxide and benzalkonium.

This has a direct implication on wine production. Biofilms caused by sodium hydroxide (or chemical filming caused by sodium metasilicate) can leave an environment where yeast, bacteria and microbes can persist on stainless steel and potentially taint your wine.

Read more here:

http://www.foodqualitynews.com/Innovation/Salmonella-biofilms-show-disinfectant-resistance

If you have any questions about caustic alternatives or better sanitation, then get in touch, because it's time to stop using caustic and start cleaning smarter, safer and cleaner.